Industrial Safety Products- Haws Portable eyewash 9 Gallon - 7501

Product Description

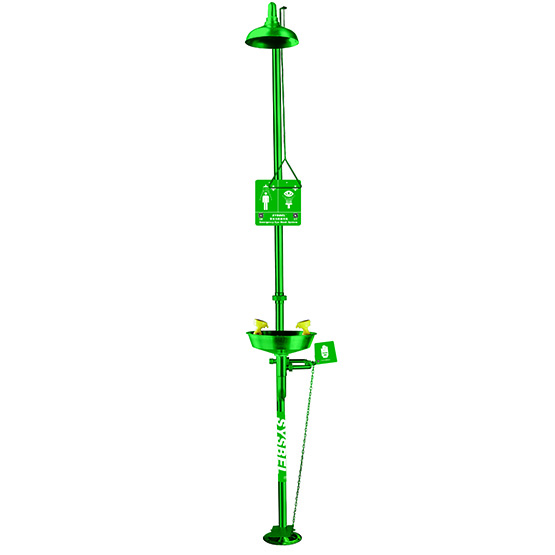

Model 7501 portable gravity operated eyewash shall include a FDA approved high-density green polyethylene 9 gallon (34.1 L) tank, ABS plastic eyewash heads with .4 gpm (1.5 L) flow rate over 15 minutes, yellow pull-down activation arm, integral handles on top and sides, wide- ll threaded cap, label-mounted operation and maintenance instructions, and a stainless steel wall bracket. Additive not included – Order separately

Where the eyes of any person may be exposed to injurious or corrosive materials, when suitable facilities for quick flushing of the eyes needs to be provided and a continuous supply of water is not available. Although the 7501 may be installed in a wide variety of locations, it is ideal for the remote and low traffic areas where protective measures are still needed. Emergency eyewash facilities shall be in unobstructed and accessible locations that require no more than 10 seconds for the injured person to reach. Model 7500 is certified by CSA to meet the ANSI/ISEA Z358.1 Standard for Emergency Eyewash and Shower Equipment.

CONSTRUCTION.

FDA approved high-density green polyethylene tank provides the light and durable construction required in a portable unit.

MOUNTING.

J-shaped stainless-steel wall bracket makes for a well-constructed portable mount for easy removal and re-mount.

EYEWASH.

Pulling down the eyewash arm will begin flushing the 9 gallon portable at .4 gpm (1.5 L) during the required 15 minutes, creating a full patterned flushing of the eyes.

DESIGN.

Tank comes complete with a wide-ll opening and threaded cap for quick inspection, cleaning, and lling. Unit also comes equipped with top and side handles making relocation easy.

In many industries in Saudi Arabia, including oil and gas, petrochemicals, manufacturing, laboratories, battery-charging stations, and remote locations, the risk of exposure to chemical hazards in the eyes is significant. In many of these applications areas, permanent floor-mounted eyewash units are either impractical or impossible to install. It is for this reason that portable eyewash stations are so valuable.

- Immediate Response Saves Vision — The first 10 to 15 seconds in the event of an exposure to a corrosive agent is critical in prevention of serious damage.

- No Plumbed Water Supply Required — Many sites in Saudi Arabia have temporary installations, remote locations, or are outdoor tanks — portable units eliminate the need for water supplies.

- Flexibility of Placement — The portable units can be placed immediately adjacent to the hazard zone or moved as the work areas change.

How to Decide Between Portable vs Plumbed

While plumbed eyewash stations are appropriate for settings of permanent hazards that have dependable plumbing and appropriate quality of water, portable eyewash units are the most equal decision if:

- The hazard zone is far away to access or the hazard zone is changing

- The installation of plumbing is cost-prohibitive

- You are looking for immediate flexibility of use and quick deployment

1. What are Eyewash Stations?

Eyewash stations are safety fixtures explicitly designed to provide a continuous flow of water to rinse the eyes when an employee comes into contact with a negative hazard; such as chemical splash, dust, flying debris and/or fumes. Portable eyewash stations are self contained eyewash units - they are used when plumbing is not available or the hazard is mobile so don't have a fixed source of water.

2. Is it alright to install a portable unit out of doors, in hot weather in Saudi Arabia?

Yes – but ensure that the station is shaded, water is conserved, and inspections are made for temperatures, evaporation, or contamination.

3. How often should inspections be made?

A visual check and activation weekly; full servicing (water change and/or additives refresh) is typically quarterly or as per the manufacture’s requirements.